Advanced Optics

Utilizing advanced 5-Axis CNC machines, SMS delivers unmatched accuracy and precision in optical component manufacturing, ranging from microscopes to custom lens holders.

Schott Manufacturing Solutions stands at the forefront of optical industry components, employing cutting-edge 5-axis CNC machines to meticulously mill components that meet the stringent demands of precision and accuracy. With the highest tolerances achievable, less than .0001, SMS crafts parts that seamlessly fit into intricate equipment like microscopes, lasers, and telescopes. Their expertise goes beyond understanding the individual component’s function; they comprehend how each part integrates into the entire project, ensuring perfect alignment within their assembly.

Challenges are the driving force at SMS, where machinists tackle complex tasks that others across the globe might shy away from.

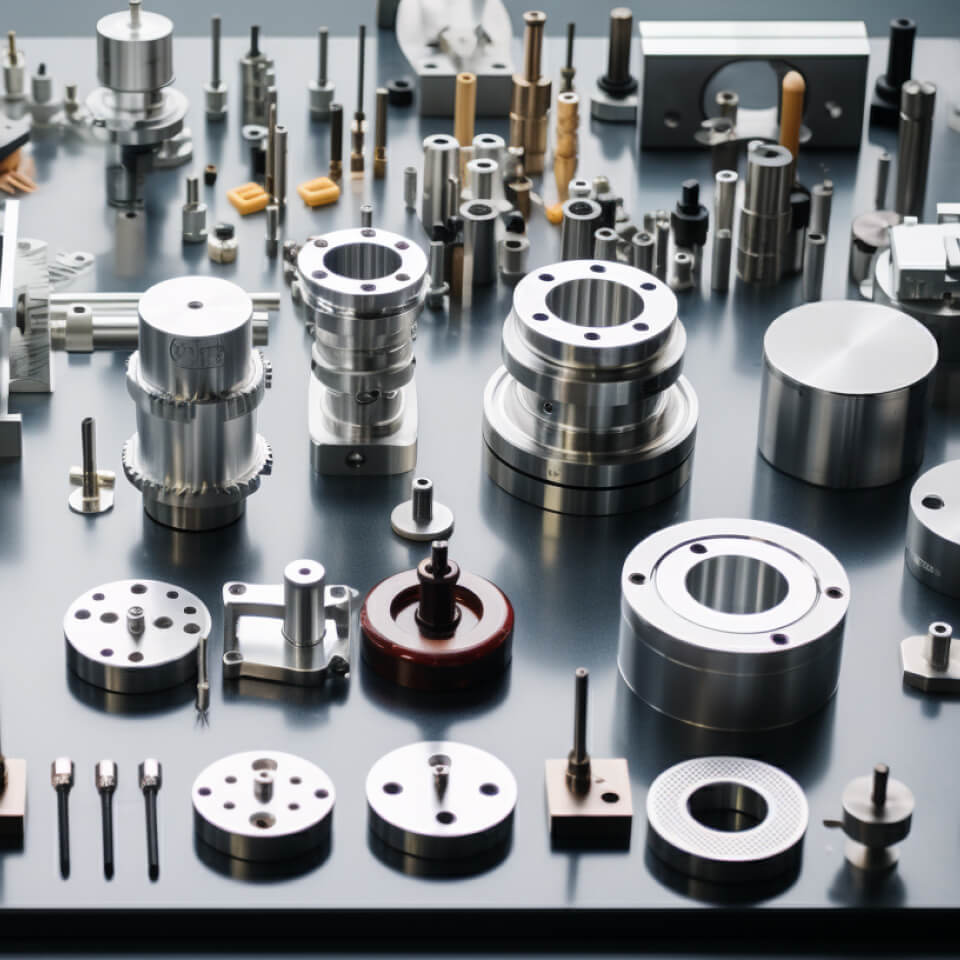

In the world of optical components, the smallest parts with the tightest tolerances can be pivotal. SMS’s CNC Swiss lathes and other state-of-the-art machining tools guarantee quality, precision, and affordability. From microscopes and telescopes to cameras and glasses, their Swiss machined products are synonymous with quality and precision, always exceeding industry standards.

Electron microscopes and similar delicate applications require specific care and precision, and SMS delivers on both fronts.

Whether crafting lens holders or designing custom components that meet rigorous requirements and regulations, the margin for error is non-existent. A recent project, an optics assembly housing for a borescope, showcased their expertise in engineering components that function accurately and are securely housed, further highlighting their unparalleled skills.

With an array of services like 5-axis milling, RAM/Sink/Plunge EDM, wire EDM, micromachining, CNC Lathes/Turning, and deburring, SMS continues to shape the future of optical components with Swiss machining.

Our unwavering focus on ultra-precision and quality materials ensures that we remain an industry leader, ready to meet the ever-evolving demands of the optical world.

The call to contact SMS is not just an invitation to experience our CNC Swiss machining lathe but a pathway to innovation and precision.

Mills

CNC mills are exceptionally adept at crafting geometric designs, meeting rapid production timelines. Our CNC prototyping capabilities encompass both 3-axis mills, suitable for various simple and complex parts, and 5-axis mills, allowing for enhanced precision and flexibility in creating intricate shapes, satisfying a broad range of manufacturing needs.

Lathe

A CNC lathe machine utilizes computer-controlled precision to shape materials. Unlike manual lathes, it automatically processes material, such as metal, into desired forms. The intricate programming allows for exact control over cutting, enabling the creation of complex, symmetrical shapes. It's vital for tasks like cutting, drilling, and deformation.

Surface Grinder

A CNC surface grinder machine is a computer-controlled tool used to produce a smooth finish on flat surfaces. It employs a spinning wheel covered in rough particles to grind away minor deformities and imperfections. By automating the traditional grinding process, CNC surface grinders ensure high precision and uniformity, making them indispensable in many manufacturing settings.

Saws

A CNC saw machine is a computer-controlled cutting tool designed for accurately cutting various materials, including metal, wood, and plastic. By utilizing precise programming, CNC saws can follow complex patterns and specifications, ensuring accurate and repeatable cuts. These machines are often used in industries that require intricate shapes and high production volumes, combining efficiency with exactness.

With state-of-the-art technologies and unparalleled expertise, SMS is defining the future of optical components. Discover how we push the boundaries of precision in crafting intricate equipment, delivering quality and innovation that transcends the ordinary.

Microscopic Precision

Utilizing 5-axis CNC machines and Swiss lathes, SMS provides the ultimate accuracy for manufacturing optical components. Achieving tolerances less than .0001 ensures seamless integration in devices like microscopes and telescopes.

Complex Challenges Mastery

The skilled machinists at SMS take on intricate and demanding tasks that other manufacturers might avoid. From crafting highly specialized lens holders to designing custom components, SMS thrives on challenges, making it a go-to solution for unique optical projects.

Affordable Quality

SMS’s mastery of cutting-edge tools guarantees quality and precision without sacrificing affordability. The Swiss-machined products are synonymous with quality and are offered at a price that aligns with industry standards, making advanced optics more accessible.

Delicate Applications Expertise

SMS provides exact precision in applications like electron microscopes, where specific care is paramount. Their experience with such delicate projects ensures that every part functions accurately and is securely housed, meeting the stringent demands of the optical industry.

Diverse Services Offering

SMS offers a comprehensive suite of solutions for all-optical component needs with an array of services like 5-axis milling, wire EDM, micromachining, CNC lathes/turning, and deburring. Whether it’s glasses or cameras, SMS has the tools to create the perfect part.

Commitment to Innovation

SMS’s focus on ultra-precision and quality materials keeps them at the forefront of the optical world. By continually adapting to the ever-evolving demands of the industry, SMS ensures that they remain an essential partner for innovation and precision in the optical components market.

Embark on your journey towards unparalleled precision and quality with Schott Manufacturing Solutions. With our state-of-the-art CNC machining, we are poised to transform your concepts into reality. Whether it's a simple task or a complex project, our dedicated team is ready to help you achieve your manufacturing objectives.