Short-run production

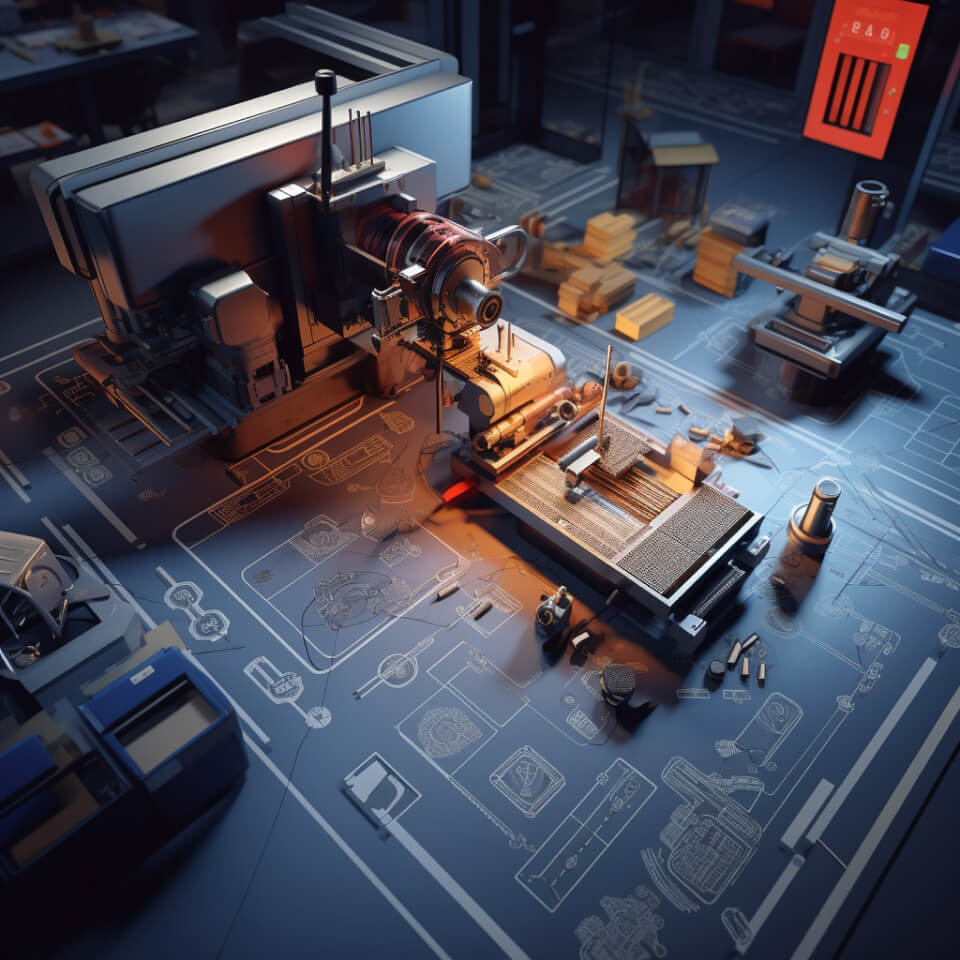

Embrace precision and efficiency with our short-run CNC production. Specializing in batches under 500, we offer rapid manufacturing for diverse parts without compromising quality.

Are you seeking to manufacture fewer than 500 precise parts swiftly? Explore short-run production, where CNC machining's unmatched accuracy blends with high-mix/low-volume manufacturing.

How We Define Short-Run Production

Your satisfaction with the sample leads to our readiness to arrange your short-run production. We define it as orders of less than 500 pieces—a process designed to manufacture a small batch of parts with incredible efficiency.

Service Details

Our facility, packed with diverse and advanced equipment, can handle an extensive array of sizes and shapes. From milling to turning, drilling & tapping, boring & threading, we’re equipped to transform raw materials into finished products. We’ve set the industry standard in offering both short (low volume) and long-run (large scale) production machining.

Precision Parts

Specializing in precision CNC machining services and prototype machining for various materials such as ferrous and non-ferrous metals, stainless, aluminum, titanium, magnesium, brass, copper, plastics, phenolic, and more, we’re your go-to partner for small to large parts.

Fast Turnaround

With lead times as short as 20 to 30 working days for short-run production orders, we’re poised to meet your specifications and align with your project timeline. Your success is our mission; our promise is a blend of quality, efficiency, and reliability.

Mills

CNC mills are exceptionally adept at crafting geometric designs, meeting rapid production timelines. Our CNC prototyping capabilities encompass both 3-axis mills, suitable for various simple and complex parts, and 5-axis mills, allowing for enhanced precision and flexibility in creating intricate shapes, satisfying a broad range of manufacturing needs.

Lathe

A CNC lathe machine utilizes computer-controlled precision to shape materials. Unlike manual lathes, it automatically processes material, such as metal, into desired forms. The intricate programming allows for exact control over cutting, enabling the creation of complex, symmetrical shapes. It's vital for tasks like cutting, drilling, and deformation.

Surface Grinder

A CNC surface grinder machine is a computer-controlled tool used to produce a smooth finish on flat surfaces. It employs a spinning wheel covered in rough particles to grind away minor deformities and imperfections. By automating the traditional grinding process, CNC surface grinders ensure high precision and uniformity, making them indispensable in many manufacturing settings.

Saws

A CNC saw machine is a computer-controlled cutting tool designed for accurately cutting various materials, including metal, wood, and plastic. By utilizing precise programming, CNC saws can follow complex patterns and specifications, ensuring accurate and repeatable cuts. These machines are often used in industries that require intricate shapes and high production volumes, combining efficiency with exactness.

CNC machined parts, known for their precision and rapid production, cater to a wide array of industrial applications:

Complex Geometries

CNC machining services excel in fabricating prototypes with intricate dimensions. Whether it features along specific axes or components with radial holes, grooves, and slots, the complexity is handled with ease.

Specialized Production

CNC machining is the go-to method for niche manufacturing applications requiring metal or plastic. It’s adept at crafting oblong or cylindrical parts, and multifaceted pieces that need cutting from numerous angles.

Automotive Precision

In the automotive sector, CNC machining offers the quick creation of functional prototypes that meet rigorous industry certification standards, ensuring quality and efficiency.

Hybrid Solutions

CNC machining provides a comprehensive solution for hybrid manufacturing initiatives. It facilitates the creation of prototypes encompassing multiple components in both metal and plastic, ensuring seamless integration and functionality.

Discover our advanced and versatile manufacturing capabilities, where cutting-edge technology meets a commitment to precision and efficiency. Tailored to meet diverse needs, we handle everything from complex designs to unique materials, delivering quality every time.

Embark on your journey towards unparalleled precision and quality with Schott Manufacturing Solutions. With our state-of-the-art CNC machining, we are poised to transform your concepts into reality. Whether it's a simple task or a complex project, our dedicated team is ready to help you achieve your manufacturing objectives.